Life Style

The Complete Hyperbaric Oxygen Chamber Maintenance Guide

Maintaining a hyperbaric oxygen chamber is crucial to ensure optimal machine performance and user safety. Whether you run a clinic or have a chamber for personal use, implementing a structured maintenance routine can extend the life of the equipment and prevent the need for costly repairs. Read on for our complete hyperbaric oxygen chamber maintenance guide—from daily cleaning practices to long-term servicing, you’ll be equipped with the necessary knowledge to maintain your equipment effectively.

Daily Cleaning and Disinfection

Hyperbaric oxygen chambers require regular cleaning, particularly after each use. Start by disinfecting all contact surfaces inside the chamber, such as the mattress or chair, walls, and the control panel. Use a non-abrasive, medical-grade disinfectant that is compatible with the chamber’s materials; this prevents contamination, reduces the risk of infection, and ensures a safe environment for every user. Also, be sure to wipe down any external surfaces that come in frequent contact with patients or operators.

Weekly Maintenance Routine

In addition to daily cleaning practices, a more thorough cleaning session should be done weekly. This includes checking the filters, air compressors, and oxygen concentrators for dust buildup or any blockages. Cleaning the filters ensures the chamber runs efficiently and prevents particles from entering the air supply. Additionally, inspect the seals and gaskets for wear or damage, as they are vital to maintaining pressure within the chamber.

Monthly System Inspections

Monthly inspections are essential for keeping your hyperbaric oxygen chamber in optimal working order. Check the chamber’s air pressure gauges, oxygen sensors, and control systems for any signs of malfunction. Examine the pressure valves and lines for wear and tear, as worn valves and lines can affect the chamber’s performance. If you notice any anomalies, schedule a professional inspection to ensure chamber safety and functionality.

Air Compressor Maintenance

The air compressor plays a key role in regulating the oxygen levels and pressure within the chamber. Regular maintenance of the air compressor is essential to prevent overheating or mechanical failure. Clean the air filters and replace them as needed, following the manufacturer’s guidelines. Lubricating the moving parts of the compressor will also help reduce friction and prolong the system’s lifespan.

Oxygen Concentrator Evaluations

The oxygen concentrators are responsible for supplying high-purity oxygen to the chamber. Ensure that they are functioning correctly by monitoring the oxygen output levels. If you detect a decrease in oxygen purity, it may be time to replace the filters or service the unit. Inspect the oxygen lines for kinks or leaks, which can lead to insufficient oxygen delivery to the chamber.

Pressure Relief Valve Checks

Pressure relief valves are vital to the safety of a hyperbaric oxygen chamber. These valves are designed to prevent over-pressurization by releasing excess air when necessary. Regularly test the pressure relief valves to ensure they activate at the correct pressure levels. Replace any faulty valves immediately to avoid compromising the chamber’s safety.

Electrical Component Inspections

Hyperbaric oxygen chambers contain various electrical components, including control panels, lighting, and oxygen sensors. Regularly inspect all electrical wiring and connectors for signs of damage or wear. Ensure that all control buttons function correctly and replace any faulty components. Proper maintenance of the electrical system helps you avoid chamber malfunctions during operation.

Sensor and Gauge Calibrations

Accurate pressure and oxygen level readings are critical for hyperbaric oxygen therapy. Ensure that all sensors and gauges are calibrated correctly. Over time, these components can drift out of calibration, leading to inaccurate readings that impact the effectiveness of treatments. Consult your chamber’s manual or hire a professional to perform periodic calibrations to maintain accuracy.

Gasket and Seal Replacements

The gaskets and seals in a hyperbaric oxygen chamber are essential for maintaining proper pressure. Over time, these components may wear out, crack, or lose their elasticity. Regularly inspect the chamber’s seals for any signs of damage and replace them promptly. Faulty seals can lead to air leaks, which compromise the chamber’s ability to maintain the necessary pressure levels for treatment.

Annual Professional Servicing

In addition to your regular maintenance efforts, it’s essential to schedule an annual professional servicing of your hyperbaric chamber. A certified technician can conduct a thorough inspection, make repairs, and perform preventive maintenance tasks that may be beyond your expertise. This ensures that the chamber operates at peak performance and that any potential issues are addressed before they become critical.

Proper Chamber Storage

When the hyperbaric oxygen chamber is not in use, proper storage is crucial. Always store the chamber in a clean, dry environment, away from direct sunlight or extreme temperatures. Ensure the chamber is deflated and covered to protect it from dust and environmental exposure. Proper storage practices prevent unnecessary wear and tear on the system when it’s not in use.

Common Issue Troubleshooting

Despite regular maintenance practices, issues can arise. Common problems include fluctuating pressure, unusual noises from the air compressor, or inaccurate oxygen readings. Keeping a troubleshooting guide handy can help you identify and resolve these problems quickly. If you’re unsure how to proceed, consult a technician to avoid worsening the issue.

Maintenance Task Documentation

Keeping a maintenance log is a good practice for tracking the condition of your hyperbaric oxygen chamber. Record each cleaning session, filter replacement, sensor calibration, and professional servicing. This documentation can help you anticipate when specific parts will need attention and ensure that your chamber remains in compliance with manufacturer guidelines.

Staff Training on Proper Maintenance

If you run a clinic, it’s important to ensure that all staff members are trained on the proper maintenance procedures for the hyperbaric oxygen chamber. Offer detailed instructions and refresher courses as necessary. Having a knowledgeable team reduces the risk of user error and guarantees that the chamber is always well-maintained.

Work With a Reliable Hyperbaric Chamber Supplier

When replacing parts or scheduling professional servicing, always work with reputable hyperbaric chamber suppliers. High-quality parts and professional expertise are essential for maintaining the safety and performance of your equipment. Reliable suppliers will also offer guidance and support, ensuring your chamber stays in top condition throughout its lifespan.

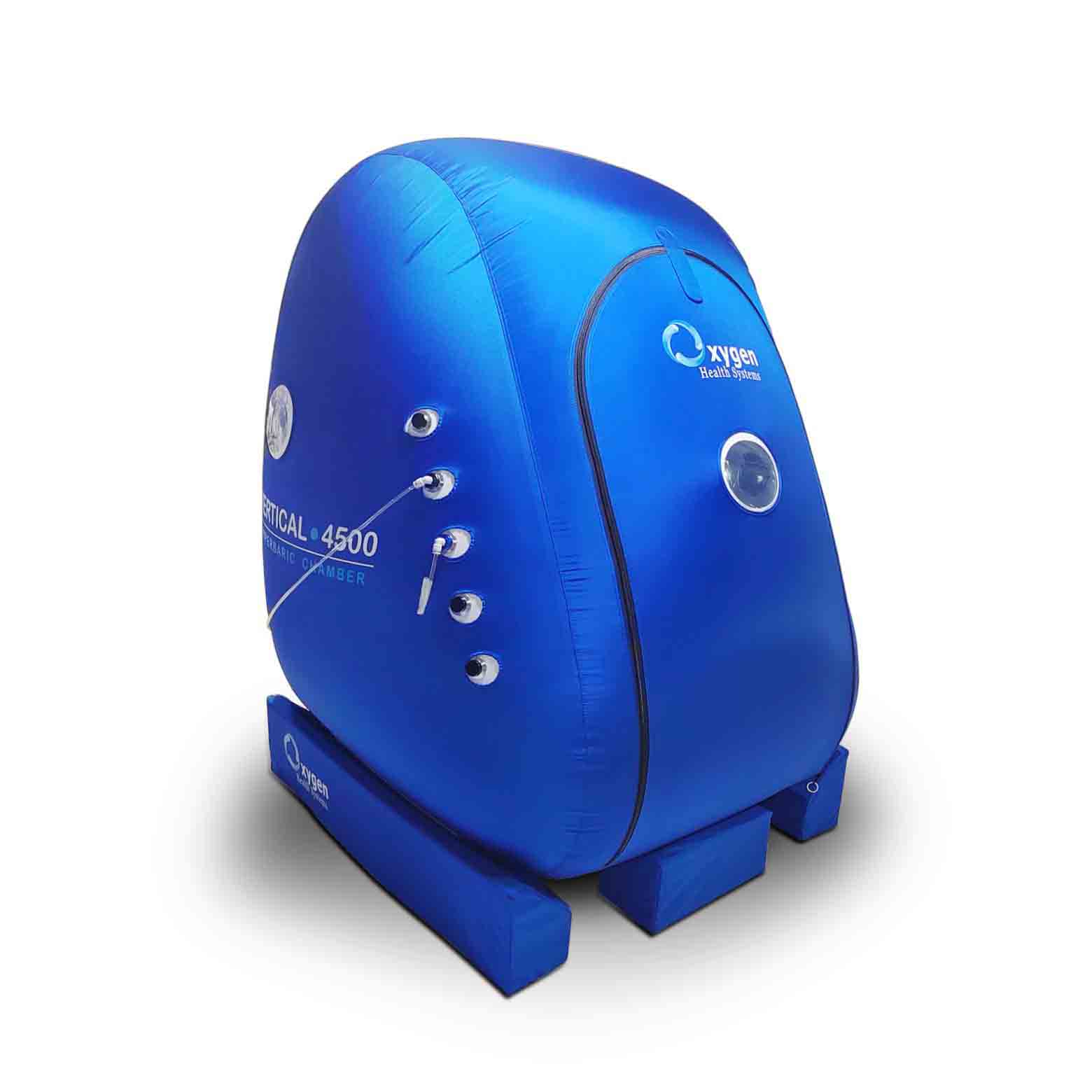

Now that you know the essentials of hyperbaric oxygen chamber maintenance, you’re equipped to keep your machine functioning safely and effectively. With a regular maintenance routine in place, your chamber will provide consistent performance—partner with a trusted supplier like Oxygen Health Systems to ensure the best care for your equipment.